Cast Iron Pipe Corrosion: The Warning Signs Homeowners Miss Until It’s Too Late

Most homeowners don’t think about their pipes until something goes wrong. And with cast iron plumbing, the problem is that the damage happens quietly for years before it becomes obvious.

If your home was built before the late 1970s, there’s a strong chance it still relies on cast iron drain or sewer pipes. In South Florida especially, those pipes are now reaching (or have passed) the end of their functional lifespan.

Understanding the early signs of cast iron pipe corrosion can mean the difference between a planned repair, and a full sewer emergency.

1. Why Cast Iron Pipes Fail Over Time

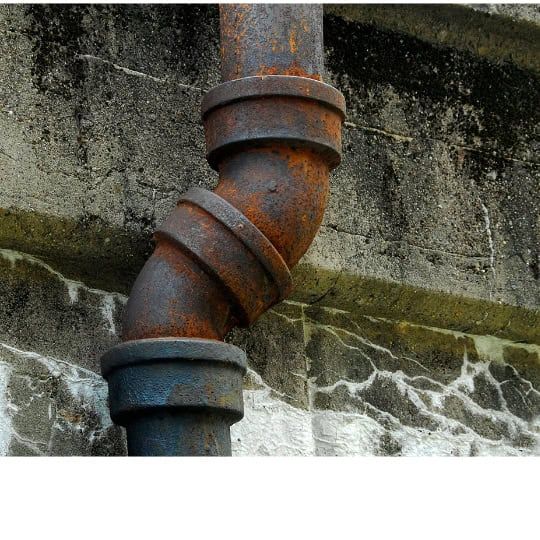

Cast iron was once the gold standard for drain and sewer lines. It was strong, durable, and quiet. But it was never designed to last forever.

Over decades, cast iron pipes deteriorate due to:

- constant moisture exposure

- acidic waste and cleaners

- mineral-heavy water

- humidity and salt air (major Florida factor)

- soil movement and settling

The result is internal corrosion , damage you can’t see from the outside.

2. Internal Corrosion Happens First (and You Can’t See It)

One of the biggest misconceptions is that pipes fail from the outside in.

In reality, cast iron usually:

- corrodes internally

- flakes and scales

- narrows the pipe diameter

- traps debris

- restricts flow

From the outside, the pipe may look fine. Inside, it may already be failing.

3. Slow or Inconsistent Drains (Early Warning Sign)

One of the first signs of cast iron pipe corrosion is persistent slow drainage.

You may notice:

- drains that never fully clear

- frequent clogs that come back

- plunging helps only temporarily

- different fixtures clog at different times

This happens because corrosion creates a rough interior surface that catches waste.

4. Recurring Clogs That Don’t Make Sense

If clogs:

- keep returning

- occur in multiple fixtures

- move around the house

- don’t respond well to cleaning

…it’s often not “bad luck” , it’s pipe deterioration.

Cast iron pipes lose their smooth interior, making normal use feel like misuse.

5. Gurgling Sounds From Drains or Toilets

As corrosion worsens, airflow through the system becomes restricted.

This causes:

- gurgling sounds

- bubbling in toilets

- noise when other fixtures drain

Gurgling is often the plumbing system’s early distress signal.

6. Sewer Odors Inside the Home

Corroded cast iron can develop:

- hairline cracks

- pinholes

- failing joints

This allows sewer gas to escape.

If you notice:

- musty smells

- sewage odors near drains

- odors that come and go

…it may indicate compromised cast iron piping , even without visible leaks.

7. Water Backing Up Into Tubs or Showers

As cast iron corrodes, the pipe diameter shrinks.

Eventually:

- wastewater can’t move fast enough

- pressure builds

- water backs up into the lowest fixtures

This is often when homeowners first realize the issue is serious.

8. Rust Flakes or Dark Debris

Another overlooked sign is debris in drains.

You may see:

- black flakes

- rust-colored residue

- gritty material after backups

That debris is often the pipe itself breaking down internally.

9. Slab or Yard Moisture (Advanced Stage)

In more advanced cases, cast iron pipes can:

- crack

- collapse

- separate at joints

This may cause:

- damp spots in the yard

- unexplained moisture near the slab

- foundation-related leaks

At this stage, urgent action is usually required.

10. Why Cast Iron Fails Faster in South Florida

South Florida is one of the harshest environments for cast iron plumbing.

Factors include:

- high humidity

- mineral-heavy water

- sandy, shifting soil

- older housing stock

- frequent rainfall

Many cast iron systems here last 40–60 years, not 100+.

11. Why Chemical Drain Cleaners Accelerate Damage

Chemical cleaners are especially harmful to cast iron.

They:

- sit in rough, corroded areas

- accelerate internal rusting

- weaken already-thin pipe walls

- increase the risk of collapse

They may provide short-term relief , but cause long-term damage.

12. Why “Just Cleaning the Drain” Stops Working

As corrosion progresses:

- snaking becomes less effective

- hydro-jetting may expose weak spots

- clogs return faster each time

This is often the point where inspection becomes more important than cleaning.

13. How Professionals Diagnose Cast Iron Pipe Condition

At Leading Plumbing Services, we don’t guess.

We use:

- camera inspections

- flow testing

- visual pipe condition analysis

- corrosion and scaling assessment

This allows us to determine:

- remaining pipe life

- severity of damage

- repair vs replacement options

Not every cast iron system needs immediate replacement , but many need planning.

14. Repair vs Replacement: How the Decision Is Made

Replacement is often recommended when:

- corrosion is widespread

- pipe walls are thinning

- repeated backups occur

- sections have collapsed

- leaks or separations are found

In some cases, partial replacement or lining may be possible.

The key is understanding the actual condition of the system.

15. Why Early Action Saves Thousands

Homeowners who act early often:

- avoid emergency backups

- prevent floor and wall damage

- plan upgrades on their timeline

- reduce total repair costs

Waiting usually means reacting during a failure , which is always more expensive.

South Florida Homeowner Reality

In South Florida, cast iron pipe corrosion is one of the most common underlying causes of recurring drain issues, odors, and backups in older homes.

The pipes don’t fail overnight , they warn you first.

Final Thoughts

If your home has cast iron plumbing, the question isn’t if it will fail , it’s when. Recognizing the early signs of corrosion gives you control, clarity, and options.

Ignoring those signs usually removes all three.

Call/Text Leading Plumbing Services today for cast iron pipe inspection and honest guidance:

(561) 506-6159